Metal Casting & Foundry 4.0 Centers

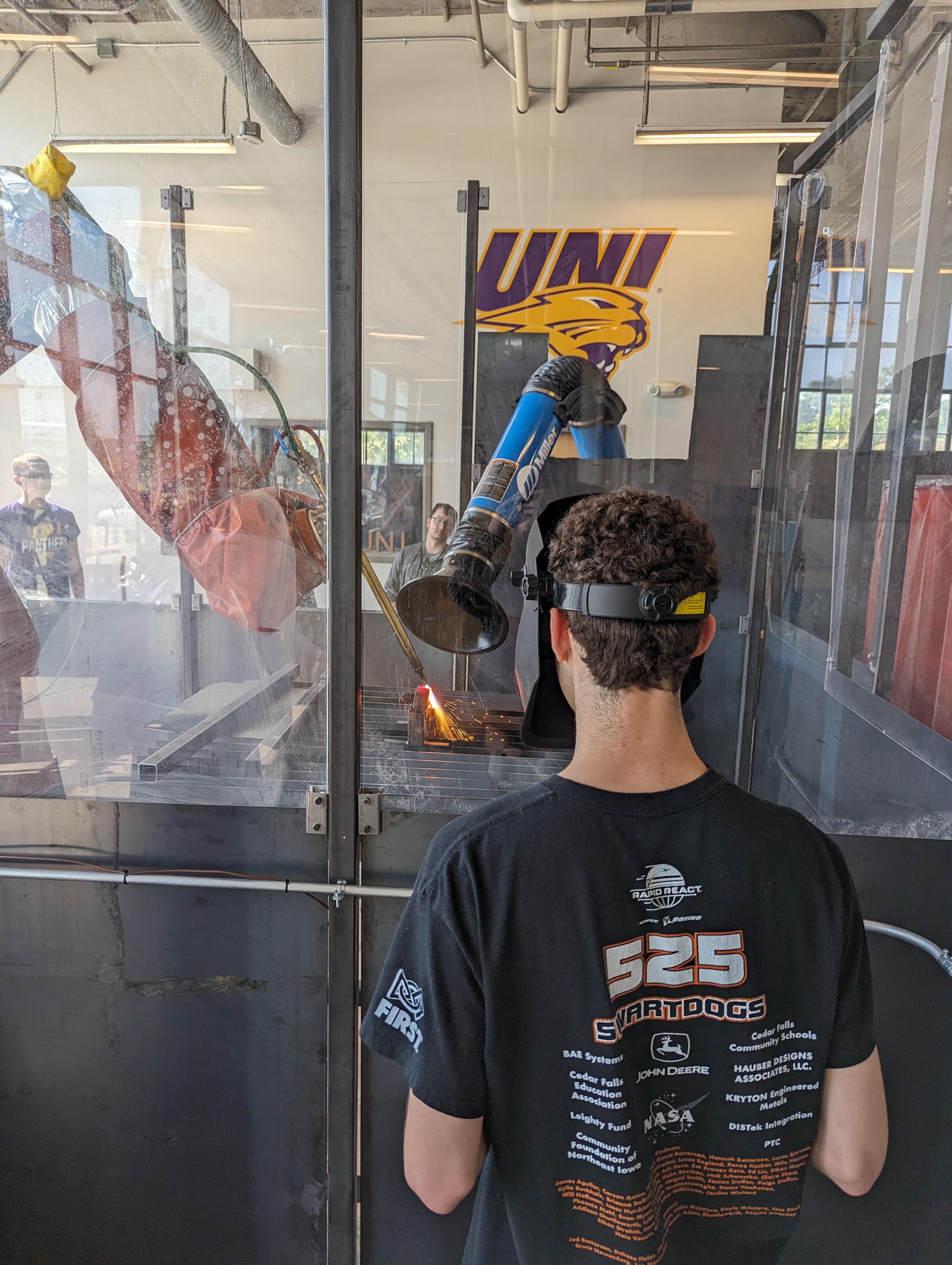

Students and staff are fortunate to have two centers to aid their research and education, including the Metal Casting Center and the Foundry 4.0 Center. UNI’s Metal Casting Center is a nationally recognized leader in foundry research, applied technology and technical business assistance. The Foundry 4.0 Center conducts research and development for the manufacturing industry in a facility that is truly one of a kind.

Currently, the Metal Casting Center is under going renovations with state of the art technologies. It is on track to be fully functional in 2024.

Metal Casting Center

As leaders in independent research specializing in metal casting materials, processes and technology, the UNI Metal Casting Center focuses on materials research, metal manufacturing and foundry education. With revolutionary metal casting, molding and 3D printing equipment, the Metal Casting Center is able to utilize its equipment to advance learning and push the boundaries of technology.

Foundry 4.0 Center

A national leader in research and development for the manufacturing industry, the UNI Foundry 4.0 Center works directly with industry partners to create new technologies and processes that improve the supply chain. This facility uses special materials and processes that are not yet commercially available to bring new technologies to the marketplace. The Foundry 4.0 Center routinely employs students for part-time positions and research work. Additionally, the center hires students from universities throughout North America for summer internships.